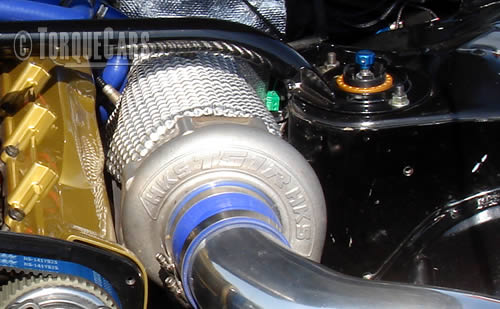

Exhaust wraps

"Ok so this is a wrap!"

Under bonnet temperatures are one of the biggest performance killers around.

Quite simply, you want your engine to be sucking in cold air as this carries more oxygen and will allow you to burn more fuel.

The exhaust system is one of the contributors to under bonnet temperatures. You can therefore lag the exhaust to help prevent this heat soak into the engine bay.

There are a couple of options which may be combined to achieve this.

Firstly, though, we will look at one of the myths around exhaust wraps. We all know that as metal gets hot its molecular structure is altered. Effectively breaking down the metal structure so many people will claim that exhaust wrap will cause the exhaust to prematurely age.

In reality the exhaust metal integrity will last for 20 years adding an exhaust wrap will reduce this to around 17 years. It is fair to say that in a cheap or badly made exhaust you may get accelerated wear.

The biggest factor in exhaust failure is rust caused by moisture and not heat. In fact keeping the heat in the exhaust will help to reduce the moisture content.

Adding a wrap will protect the outer surface of the exhaust from water so there is actually more to be gained from adding an exhaust wrap than not having one.

Because you are keeping the exhaust gases hotter you will find that they flow better out of the engine. Turbo owners will experience slightly reduced lag as a result of the faster flowing exhaust gases.

So what are the exhaust wrap options available? Firstly there is a thermal bandage type wrap which you wrap around the exhaust. It is important to keep this tight and overlap the previous layer slightly with each rotation. Small gaps in the wrap will have little of an effect so you don't have to be paranoid about coating the whole downpipe.

The other option is a bonded ceramic coating applied to the exhaust. Ceramic is a very poor conductor of heat so is ideal to have on an exhaust. A ceramic coating also looks much neater with a powder white/cream finish on the treated surfaces.

The ceramic coating is applied in spray form under extremely high temperatures causing it to bond with the exhaust surface. Preparation is key. If the exhaust surface is poor then you will potentially suffer from peeling and flaking.

You can always apply both a ceramic coating and a wrap and increase the thermal insulation of the exhaust.

How much will the under bonnet temperature reduce by? We have seen claims of 30-40% for ceramic coatings and upto to 60% for exhaust wraps. By combining both methods you could reasonably expect to hit nearer the 50% mark.

How much of the exhaust should be wrapped? TorqueCars would expect the optimum effect would be to completely wrap the headers and downpipe to the catalyst.

A hot catalyst is more efficient so your catalyst will last longer if you apply a wrap.

There is nothing stopping you from wrapping the entire length of the exhaust but you need to remember that the aim is to reduce the under bonnet temperature.

Other budget options which can be affective include using high temperature paint and silver foil.

You still cant beat something made for the purpose though in terms of cost to benefit.

Join us in our forum to discuss exhaust wraps in more details where our members will be able to pass on their tips and experiences.

If you liked this page please share it with your friends, drop a link to it in your favourite forum or use the bookmarking options to save it to your social media profile.

Check out TorqueCars new YouTube channel, and see their awesome new content...

Feedback

Please use our forums if you wish to ask a tuning question, and please note we do not sell parts or services, we are just an online magazine.

Help us improve, leave a suggestion or tip