Effect of big Intake valves on engine power gains.

"A sharp intake of air."

The heads primary job is the mixing of fuel and air and delivering this to the combustion chamber.

Any turbulence or drag can restrict the air flow into the engine starving you of power.

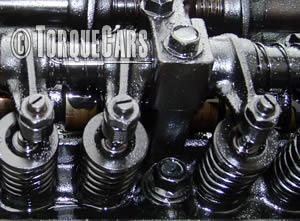

So this TorqueCars article will focus on the intake valves (center of the cross section picture).

The aim of head tuning is both to maximise the amount of air and fuel that gets into the engine, and to improve the mixture.

We have another article on porting and polishing so we are going to focus on the job of the valves and lifters.

Intake channels

The intake ports in most cars are at 70-90 degrees of the combustion chamber, requiring the air to turn as it enters the combustion chamber. For practical reasons the intake ports cannot run vertically into the engine as you have to negotiate the camshafts and other engine components. The more shallow this curve the better the flow rate you will get. So the job of porting changes the dimensions and angle of airflow through the head into the engine.

Making the channels that lead into the head wider, will also help to increase the flow rate. Just as with exhaust design you need to avoid steps and sharp bends. If you have to reduce the bore of a channel, this must be done as a gradual cone shape. Remove any burrs or metal seams and smooth the head as much as possible.

The valves are like little trumpets, which open to allow air into and out of the engine. The duration that these valves open for is the job of the camshaft but the lifters decide how wide the valves open. If the valves open too much it is possible to have them crash into the piston which is obviously not good. If the valves bounce you will lose power or suffer from engine damage.

Maximising the airflow into the engine with larger inlet ports will also require larger valves. There is little point forcing more air into an engine if there is a restriction in the valve size.

Valves must be properly seated and mate well to the surface inside the engine when they are closed or you will lose power. A valve seating paste will help with this.

By using a drill and and old valve with the abrasive paste grind the valve seat smooth, making an air tight seal when the valves close. Older engines will usually benefit from re-seating valves, particularly if compression is down across all the cylinders. At this point an owner will start to look at big valve conversion kits.

Instead of opting for larger valves many manufacturers increased the number of valves. We now see most engines with 16 valves which theoretically channel almost twice as much air as 8 valve engines. The VAG group have even produced an engine with 20 valves which has an over sized exhaust valve (more air volume exits the engine due to heat expansion!)

The size of valve you choose is restricted by the amount of space there is at the base of the head. You cannot overlap valves, and valves cannot open if they scrape the cylinder wall. Some manufacturers use valves which are peanut shaped allowing them to fit 2 closer together.

The valves will open and close at a fast rate, especially in a performance engine so attention must be made to the springs and retainers which can wear at an alarming rate. Springs come in different grades and allow some control over the rate at which the valves open and close. Listening to the top of the engine will give you an idea of the condition of the valves and lifters.

Often, instead of fitting big valves to your engine, you may have the option of fitting a 16 valve head to an 8 valve engine from the same manufacturer. But you need to exercise caution.

Taking the Rover 1.8 VVC head as an example this would technically fit on a 1.4 block provided the 1.4 engine is rebored to allow the valves to clear the liner wall.

Some heads are interchangeable where engines have the same block design, such as the VW golf 8v and 16v heads, this require little more than a few timing/electrical tweaks to work. The key is to do your research, it might look like it fits but there could be a whole set of obstacles in the way.

Check the cams for wear because some motorsport cams are made of a softer material and will wear quickly. Run your finger nail at a 90 degree angle over the cam to check the surface for wear. The surface should be smooth and not dip in the center. A worn cam will dramatically decrease the amount the valve can open.

If you liked this page please share it with your friends, drop a link to it in your favourite forum or use the bookmarking options to save it to your social media profile.

Check out TorqueCars new YouTube channel, and see their awesome new content...

Feedback

Please use our forums if you wish to ask a tuning question, and please note we do not sell parts or services, we are just an online magazine.

Help us improve, leave a suggestion or tip